Allan Byrne

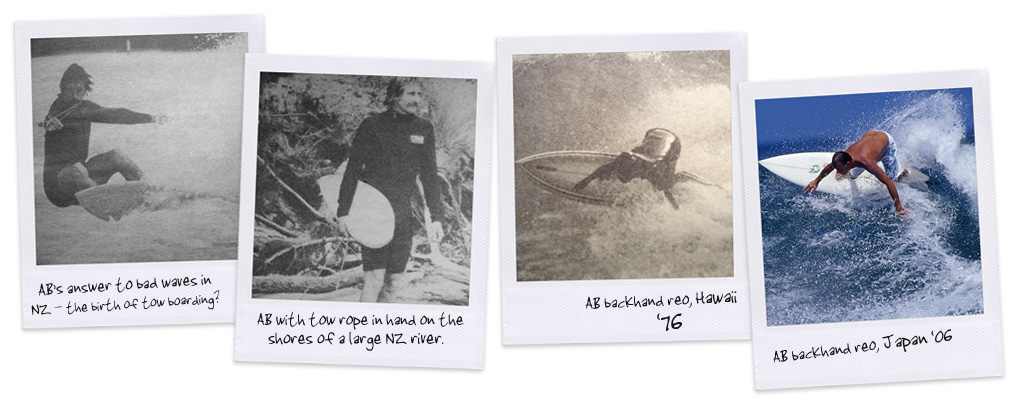

A gifted craftsman, AB is renowned for his orginal hand-shaped channel-bottom boards. Originally from New Zealand, Allan started shaping boards on the west side of O’ahu in ’69, eventually moving to his present location on Australia’s Gold Coast.

Dedicated to his craft, Allan travels throughout the world to places like Whangamata New Zealand, Kaifu Japan and the North Shore of Hawaii where he continually trains his shapers and updates designs as he has done for the past 3 decades.

Allan Byrne is not only the greatest artist of channel bottoms but one of the worlds best and most respected surfboard shapers.

An insight into the shaping life of Allan Byrne from 2010:

A gifted craftsman, AB is renowned for his orginal hand-shaped channel-bottom boards. See why Allan Byrne is the master shaper and get an insight into the new FCS AB fins.

Al you’ve been shaping surfboards for 40years and most people are aware of the Byrning Spear and its superior performance. How important are fins and fin designs to the performance of any surfboard?

Well fins are like aerodynamics the tail plane the trim tab/ailerons they’re called control surfaces on an air craft and that’s what fins are on our surfboards, control surfaces. I always say to people I can put a really good set of fins onto a shitty shape and it will make the board go good, but I can’t put a shitty pair of fins onto a really well shaped board and make it go good, they’re really really important the single most important thing in surfboards is the fins, more important than lumps and bumps inaccuracies and all that stuff. It’s always been my pet thing because of my knowledge about aerodynamics.

Back in the hand foil days when we had glass on fins I was forever getting guys commenting, I would send a board out and guys would go, “ah you no what its just not quite right” and they would bring the board back in and I would spend five minutes and I could take 2 millimeters off the back of the fin and redress it back in and it would change the board from a dog into the best board they have ever had, that’s how important fins are. 90% of the boards on the planet at that stage were not performing up to there potential cause they had shitty fins. FCS had really shitty fins then, they were plastic, they bent, they didn’t have any return in the flex, and it’s all changed.

As a young guy you joined the Air Force, did wing foil and aerodynamics play much of a role with your shaping and fin design?

Yeah it sure did, made a world of difference, as an airforce cadet one of the things when we did aerodynamics was that we studied a lot of movies with wind tunnels and smoke trails and we could see, separation, cavitation forming off a wing with changing angles of attack and all these different things, I can still see that to this day, when I close my eyes I can put a fin in the water and I can relate to breakaway and why the fin isn’t going to work, it was just amazing how much help that was when working on fins, and because it was so long ago it has pretty much encompassed the rest of my shaping life.

Would you apply these same concepts to tow in boards where your speed is through the roof?

Yep sure, sub sonic and supersonic flight, two different aerodynamic principles, like this, aerobatic low speed foil is fatter towards the leading edge, softer leading edge, fatter foil, in a high speed foil it’s a sharper leading edge the centre or fattest part of the foil is back more than a third, they’re two different principals. When you get into giant waves, like I work with Darrick Doerner he’s kinda like the brains behind the giant wave stuff, we made tow boards for about seven years with inferior fins, we glassed them on we tried all these things and nothing seemed to work and it gave us the impression that we were doing the wrong things with the hulls, like in the shaping side of things, we kept saying its cavitating, its because of a problem in the bottom, there’s a ‘V’ here and it shouldn’t be there ‘What are we gonna do?’and none of them worked until Darrick who was working with Future Fins came up with the 80/20 foil, they went from a 50/50 to a 70/30 and ended up on the 80/20 which is pretty much a wing foil, and suddenly what we thought was shitty shaped boards were working and so it dawned on us even in the tow boards the fact that all the tow boards were working with the 80/20 foil that the Future Fin System had really made every single surfboard work well, but without the right fins none of them worked very good. There’s two different realms here, towing in under 25 feet and over 25 feet fins are really really important. .

You said to me once, ”I could make a living standing on the beach at snapper rocks with a piece of sandpaper and a sanding block and in 10 minutes change the total performance of a board to where a surfer could not even recognize his own surfboard as it would surf so well”.

That’s absolutely true. Here’s an example, we have a really big problem in surfboards globally at the moment where there’s cheaper asian things coming in, there glassing is ok, there shaping, well they’ll get that right but unless you surf you don’t understand how important and crucial foils and edges are. You know how I spoke about that 2millimeters in the tip of the fin, whether it’s fatter in the tip or narrower, is there a little flat spot on the back of the edge that you can barely see? That can cause cavitation vibration and humming, with a rail edge if you shift that up a board by 2inches with incorrect sanding its going to make the rail project longer it’s going to make the board catch coming off the top, so when I made that statement to you about Snapper, 90% of the boards haven’t been tuned properly and I could stand on the beach and watch the guy surf on his board look at where the boards not working right, he could come in and I could just give it a little tweak here or there and it would change the performance of the board unbelievably so.

The reactions I get from guys who come into the factory and go, ah this bloody board’s not right, it wont turn and it wont do this. I would make them stand there and watch, it would take 10 minutes and they would say that’s not gonna fix it, it’s just a little sand here or there. I’ve always given a performance guarantee with my boards, three days later I’d get a call from one and he’d say “wow I can’t believe this board, this is a completely new board!” That’s the subtleties that are beyond shaping, beyond anything, that’s the subtleties that come from a custom made surfboard by people who have been in the industry long enough to know and its becoming a forgotten art. In mass production factories where there’s a lot of people, in dry cutting and wet rubbing its always been considered the job that’s on a parallel with sweeping the floor, you get to sweep the floor first then you get to do dings, then they put you on dry cutting and wet rubbing. You’re then responsible for the finest tuning that will make the board go 50% better then it would normally go. It’s one of those grey areas that people don’t realise that’s the really important part. There’s a quote from Al Merrick, I read it somewhere and he says, “It’s all in the 100 grit, that’s the coarseness of the sandpaper when you’re finishing the board off, that’s when you put your rail edge on and when you tweak your spine on the V or finish off the fins and control surfaces, those are the things that are going to make or break a surfboards performance”.

Recently FCS did you the honor of manufacturing your own fins into the FCS range.

I’m stoked, cause FCS came to me two and a half years ago and said that they would like to do my fins and they had to be good enough cause I had this other guy ‘feather’ do me some fibreglass FCS fins. Fins have got to be fibreglass, at the moment there is nothing that gives the flex return and twang, you know that little squirt that a fin should give. I said to FCS “they’ve got to be as good as this and they must be in fibreglass” so they went ahead and I gave them a set of ‘Feathers’ and they went off did them with computers and applied foils in the NASA catalog and applied them to my template and its made the performance of my surfboards exceptional.

The hardest thing for me prior to this when we were hand foiling was that I didn’t necessarily get to check every board and was reliant on the sander to do the perfect job on every single board that went out, the sander was responsible for getting that fin the right size and shape and the process would fall over, now FCS give me my fins and every single set is absolutely perfect, so when I make a board now and put those fins in I guarantee the performance and now when I say to people if this board doesn’t go I know its my fault, it’s not the fins fault, and it ain’t gonna be the edges [rails] fault because Dale Wilson does that sanding, so the FCS fins have really solved a lot of issues for me.

The hardest thing for me prior to this when we were hand foiling was that I didn’t necessarily get to check every board and was reliant on the sander to do the perfect job on every single board that went out, the sander was responsible for getting that fin the right size and shape and the process would fall over, now FCS give me my fins and every single set is absolutely perfect, so when I make a board now and put those fins in I guarantee the performance and now when I say to people if this board doesn’t go I know its my fault, it’s not the fins fault, and it ain’t gonna be the edges [rails] fault because Dale Wilson does that sanding, so the FCS fins have really solved a lot of issues for me.

I believe there’s an AB1 and an AB2, tell us what the difference is here in the two.

Well the AB1 is a standard flat inside foil, it works as all fins are supposed to work, it projects a little longer and makes the board go kinda normal. The 2’s have an 80/20, that’s 20% on the inside foil and 80% on the outside, these are only on the side fins, that makes the fin far more efficient, has less drag, its faster and it also leads into turns quicker, the best description of what that does is its like having power steering on your car, you think turn and the board starts to turn. I tend to use them on the guns to make them surf shorter, they’ll shorten the arc of the turn, the way I work with those two sets, if the surfs smaller I will put the 2’s in the same board and as the waves get larger I’ll put the 1’s in as I can make the board surf longer than it should, so shorter boards put the 1’s in, longer board put the 2’s in.

Just recently Dylan Longbottom took the 2’s down to ShipSterns, they put those in the tow boards, I was mentioning earlier in the interview that under a certain wave size, say 15 feet and down, they used the 2’s in that and because they’ve got a more efficient fin that doesn’t fail under pressure, they used those in the tow boards and had phenomenal success out of them. What FCS are going to do is release a tow fin for 25 feet and up like the extreme end of the scale and that has an 80/20 foil but very reduced side fins and a substantially larger tail fin, and as there mid range tow fin they’ll have the AB2 available for that, whether they still call them the AB2’s I don’t know.

How do surfers go about buying a set of these?

At the moment you’ve pretty much got to come through me at the factory here and get them put in your new board, (if you want a set contact Al now) or you can get them from the Boardroom in Miami on the Gold Coast here, or from the Quicksilver board shop in Manly, only the shops that are dealing with me at the moment but I’m presently working with FCS to try and release them to the public but this could take a few months to sort out before they are available, I’m hoping they will be available on the Byrning Spears web site soon.

So there you have it from the guru of shape, all the goss on cool fins that will turn your Volkswagen into a Ferrari……………Thanks Allan Byrne from Byrning Spears.